Your product quality, powered by TEKTOS

Manufacturing Quality Expertise

Our engineering team takes a hands-on and detail-driven approach from design to validation. We work with companies from different industries, bringing trusted quality engineering practices to help solve their unique production challenges.

User-Centric Approach

Every test we conduct is designed with the end user in mind. By replicating real-world conditions such as drop, vibration, environmental or long-term wear, we build products that people can count on for performance, safety, and durability in everyday use.

Certified Quality & Compliance

We follow globally recognized standards, and best practices to make sure our work meets strictly safety and compliance requirements.

-

Extreme Condition Reliability Testing

We expose devices to extreme temperature changes, from freezing cold to intense heat. We monitor how each component reacts at every stage. Batteries, plastics, sensors, adhesives, and seals behave differently under stress, so we track signs of deformation, chemical expansion, sensor drift, wireless performance, and even how the enclosure reacts to heat. We run these tests repeatedly to mimic years of normal use in just a few days.

-

PCBA Visual Inspection

We examine each PCBA using magnification and structured inspection criteria. This includes checking solder joints, part alignment, lead conditions, flux residue, pad wetting, component height, and any signs of cold solder joints or bridging. We compare our findings to IPC standards and our internal data. When we notice a recurring issue—even one that hasn’t caused a failure—we trace it back to the specific process or machine setting responsible.

-

Connector Durability Evaluation

Connectors often define the lifespan of a device. Through mechanical cycling and environmental stress, we validate connectors that will withstand real-world use. Because reliability depends on the parts people rarely see.

-

Ripple Noise & Signal Check

Poor power quality is a common cause of unstable product behavior and often one of the hardest to diagnose. By using oscilloscopes. we can visualize transient spikes, harmonics, switching ripple, and power-rail behavior across various frequency ranges.

-

Material Composition Analysis

Material inconsistencies often only become apparent after months of use—when it is too late. By verifying composition early, we prevent failures caused by inferior or off-spec materials.

-

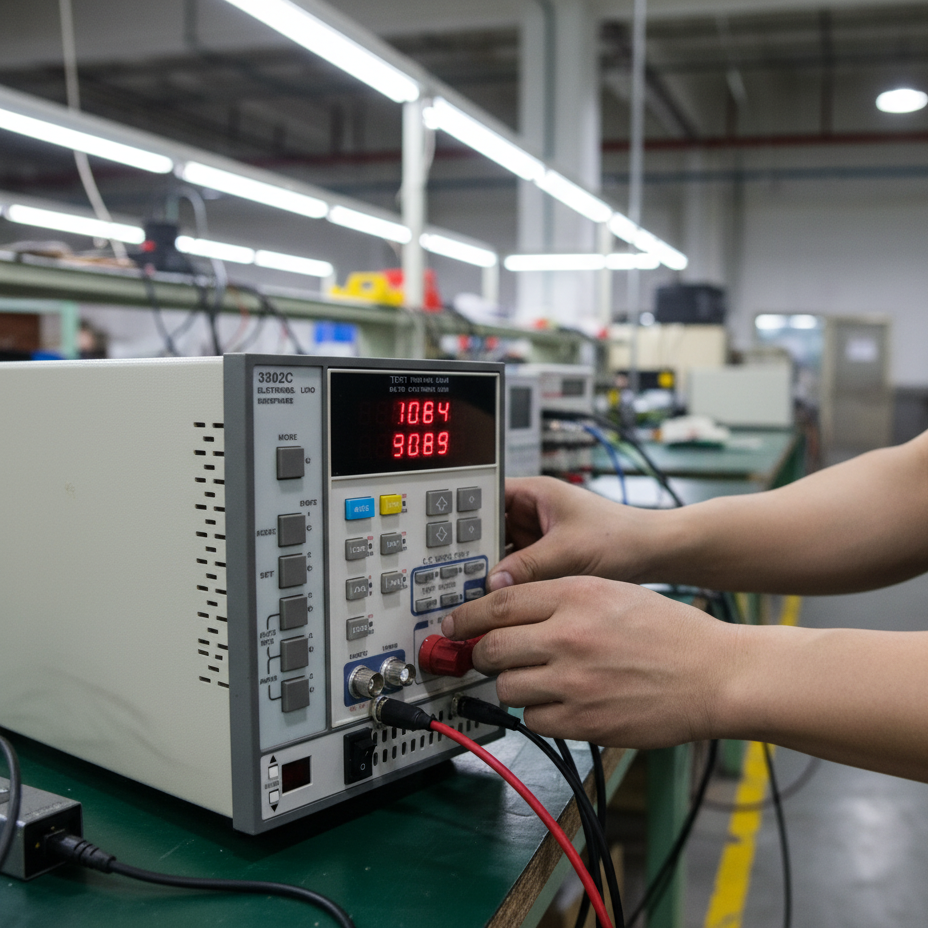

Power Supply Load Test

We stress power supplies with realistic simulated loads, including sudden surges, high-current draws, rapid switching, and unstable inputs. Stable power delivery keeps the entire product functioning correctly and safely. This testing helps prevent overheating, unexpected shutdowns, and long-term wear.

-

Temperature Measurement

We use this digital thermometer to check surface or surrounding temperatures during production and testing. It helps us make sure that parts and equipment don’t get too hot and that everything runs within the right temperature range. That way, we can catch any issues early and keep quality consistent.

-

Insulation & Withstand Voltage Check

Hi-Pot testing protects against electrical shock, short circuits, and fire hazards. It is a crucial requirement for global safety compliance, and we take it seriously.

-

Cables, Wires & Connectors Retention Check

We measure the force a connector can handle before loosening, detaching, or damaging its housing. We simulate twisting, bending, repeated pulling, and sudden jerking—common stresses that users often overlook.

-

Battery Aging Test

We expose products to vibration cycles, flexing stress, constant loads, and mounting tension. This testing uncovers hidden design weaknesses before mass production, allowing us to strengthen the structure where it matters most.

-

Cable Wire Breakage Resistance

We bend, twist, flex, and pull cables through thousands of cycles. We analyze conductor fatigue, insulation cracking, and points where stress concentrates. Improved cables lead to fewer customer complaints, warranty issues, and long-term product failures.

-

Volatage Accuracy & Load Handling

We test our chargers under different loads to check if they deliver the right voltage and current. This helps us make sure they perform safely and reliably in real world use.

-

Automated Functional & Load Test for Travel Chargers

We automate tests for output stability, heat management, load response, and compatibility across various devices. Each charger undergoes multiple loading scenarios to verify consistent performance. Automation guarantees that quality is not left to chance; every unit is tested to the same standard.

-

Free-Fall Drop Test

We drop products from various heights, angles, and orientations to watch how the enclosure, PCB, battery, and connectors respond. After each drop, we inspect for hidden internal damage.

-

Corrosion Test

We expose parts to environments that accelerate corrosion to test coating effectiveness, material quality, and long-term durability. This testing ensures that products intended for outdoor, marine, and humid environments retain their performance over time.

-

Needle Flame Test

We assess flame resistance, dripping behavior, and self-extinguishing properties under standardized flame conditions. This testing ensures our products comply with global safety certifications and protect users in extreme situations.

-

Universal Test Machine

We measure tensile strength, compression, shear resistance, deformation, and long-term fatigue. The results help us choose the right materials for their intended functions.

-

Ultrasonic Welding Machine

We refine welding settings to match material thickness, shape, and structural requirements. This results in precise, durable joints without the need for screws or adhesives.

-

Vertical Injection Molding

We mold prototypes in-house, adjusting gate placement, managing shrinkage, and controlling cooling paths. Each cycle improves manufacturability and product feel.

-

PCB Test Jig

Every board goes through continuity checks, functional tests, firmware loading, calibration, and electrical verification using a custom jig. We log results for traceability.

QC & Certifications

-

We develop guidelines towards cosmetic, functionality and reliability for product inspection.

Manufacturers accepts and adheres to TEKTOS Standards to be an approved vendor.

-

Norm Compliance

Production management QC processes, IQC, in-line QC and in-packing line QC are operated by dedicated TEKTOS engineering staff at our suppliers and subcontractors' premises.

Factory Auditing

We guarante 100% traceability in each and all of the QC steps inclusing product and carton traceability upon export.

In-House Laboratory

This level of qualitative operational production management is applied to each and every product we supply.

-

Define

Design Standards Manufacturing

Standards AQLValidate

Components & Material IQC

TEKTOS Test jigs on production lines

Mandatory TestControl

Independent QC of all production

Destructive and Non-Destructive Test

Full reporting on each productionTrace

Full product traceability

Vendor, Week, VersionImprove

Feedback and action on defects